The pneumatic nozzle is capable of producing a high fineness droplet size all by mixing compressed air and liquid. Its advantage is that the amount and quality of atomization can be well controlled with the auxiliary air, and it also allows the atomization of more viscous materials.

Generally with pneumatic nozzles, the volume to be atomised can be very finely controlled by separately regulating the air and medium pressures.

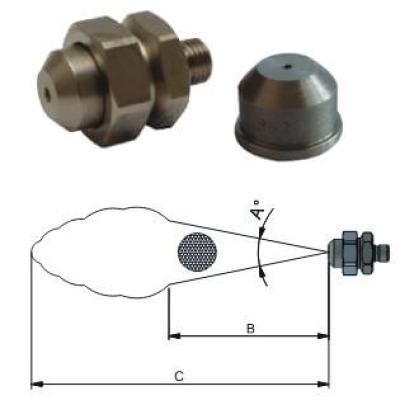

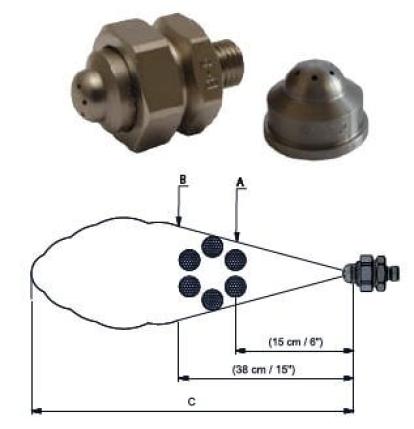

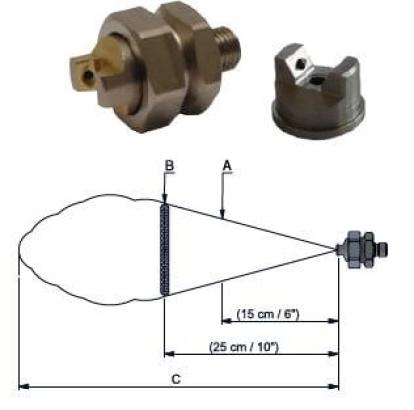

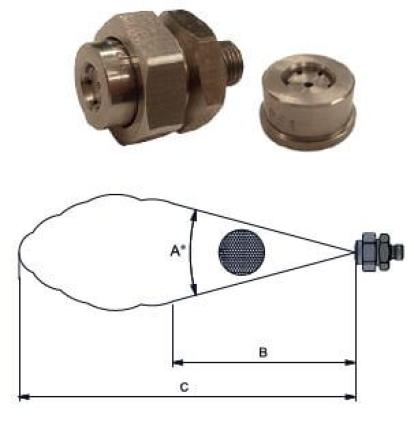

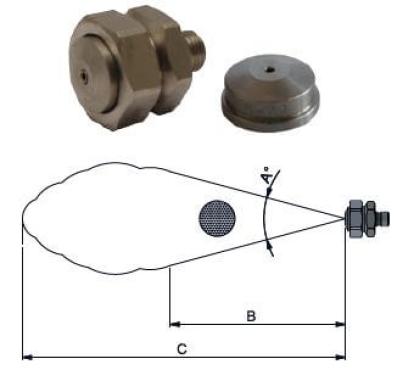

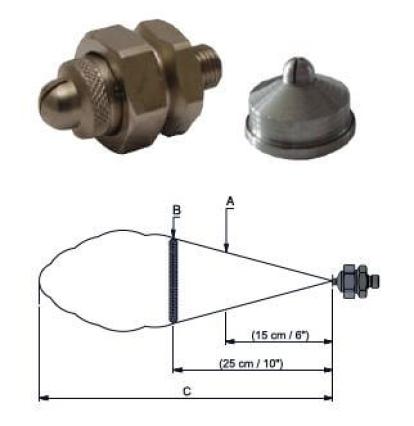

The pneumatic nozzle can be internally or externally mixed depending on the viscosity of the medium to be atomised. Its spray pattern can be full cone or flat jet. The pneumatic spray nozzle can be operated according to 3 principles making it easy to adapt to the available operating conditions: liquid pressure (a suitable pump is required), gravity (inflow) and siphon (self-priming).

Further advantage of the pneumatic nozzle is that it can be equipped with various accessories, which can be operated manually or automatically, depending on the specific production process, such as e.g. opening-closing needle valve or cleaning needle. In the case of externally mixed models, the volume flow of liquid and air can be controlled independently of each other, and it is also possible to adjust the spray pattern.

Pneumatic nozzles are available in two versions, with two passage and three passage nozzle bodies. The two passage pneumatic nozzle has two inlets, one on the medium side and one on the air side. Three connections have been made on the three passage pneumatic nozzle body, which allows for a closing air connection in addition to the previous two. With the help of the closing air-operated shut-off needle, we can control the spray cycles of the nozzle, i.e. close and open. If the nozzles in an application area are required to operate absolutely drip-free, a "no-drip" shut-off needle must be installed in the three-passage nozzle body.

Another way to achieve perfect drip-free is the ultrasonic pneumatic nozzle. With this type of pneumatic nozzle, the finest droplet size and the smallest amount of atomized medium can be achieved.

FIELDS OF APPLICATION

Atomizing of viscous media, humidification, wetting, cooling, coating, spray drying, gas cooling, waste incineration, flue gas desulphurisation, track humidification, lubrication, continuous casting