Surface treatment, pre-treatment before painting, cleaning and degreasing are gaining more and more space in our everyday life, as non-stick paint, unevenly applied paint and poor surface quality pose serious quality problems.

A complete nozzle palette is available for surface treatment!

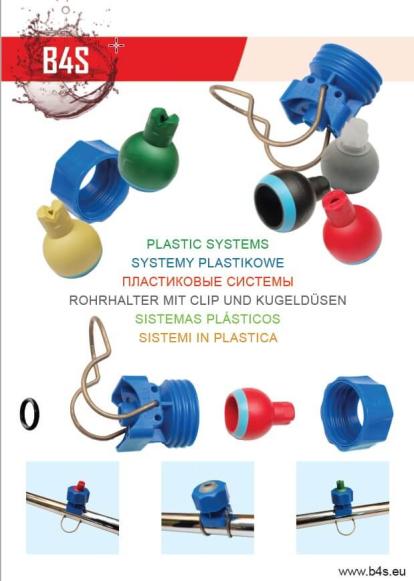

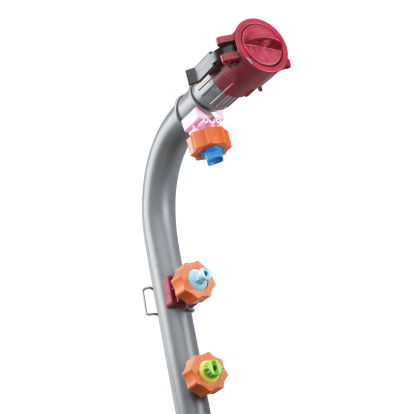

The most typical of the surface treatment is the use of ball nozzle systems and memo nozzle systems.

The nozzle systems are fixed with clips (pipe clamp spring) or with a mounting clamp or pipe clamp solutions. Clamps and clips are available for different pipe diameters (1 ", 5/4", 6/4 ") and with different bore sizes (= hole diameter on pipe)

The bore diameters can be: ø14, ø17, ø20

The ball seat on the clip and on the pipe clamp is the same size in all cases at all pipe diameter, so that the balls with different flow capacity can be exchanged free in it. The ball in the seat can move freely in all directions. After setting the right and requested direction the position of the ball is fixed with the locknut.

The ball nozzle systems basically have two types regarding the nozzle:

1) ball + nozzle as a unit, molded together

2) ball + fitted with some nozzle

If we fit a nozzle in the ball it all offers the following options:

1) threaded ball with threaded nozzle (nozzle material can be stainless steel to)

2) memory ball and memory nozzle fixed with bayonet connection

The advantage of the memory nozzle is that it "remembers" the setted spray direction. Since the nozzle can be fixed in one motion with the connection of the ball and the bayonet, the nozzle can be removed independently of the ball. The ball is placed in the ball seat and its direction is adjusted and fixed with the locknut. The nozzle is then inserted into the ball and secured with a bayonet connection. The ball thus already gives direction to the nozzle.

This solution is important where there are hundreds of nozzles in the pre-treatment tunnel on the pipes and the quick return of the nozzles in the original spray direction is very important after cleaning. (downtime is expensive)

Nozzles in surface treatment:

Spray tunnel process

The nozzles are placed on pipe wreath in the tunnel, while in the tunnel the workpieces are hanged on the konveyor track. The surface of the workpieces is sprayed with chemicals that are applied to the surface by the nozzles.

In most cases the nozzles have a flat fan pattern because the workpiece is in motion.

However, there are also tact system pre-treatment tunnels where the workpiece is stopped for a while. In these type of pretreatment tunnels we mainly use full cone nozzles. (Exceptions when the time and distance of movement is sufficient to apply a flat jet nozzle).

In most pretreatment systems the workpiece is in motion using the konvejor track and the nozzle wreath is static. However at places where space is limited and not sufficient to build a pretreatment tunnel of adequate length the wreath are moved.

In these cases the number of nozzles is less as is the number of pipe wreath and the tunnel is significantly shorter. For the nozzles, the medium is led from the pump by a flexible hose.

The typical pressure in the pretreatment systems is approx. 1.2 to 1.6 bar.

The medium is supplied to the nozzles by a centrifugal pump, which is usually a centrifugal pump with a horizontal axis.

- KTL line

Where a large quantity and similar size of workpiece or product is produced, where an even surface is important, KTL painting produces adequate results.

KTL pretreatment is practically a dipping tub process where the workpiece is dipped in a low solids paint dissolved in water.

Here, the ball nozzles occur in the pretreatment, where ball nozzles are used to spray and spread the workpieces in the basket.

It is necessary to circulate the contents of the tubs, so circulating (ejector, venturi) nozzles are used in these tubs.

In this process, the number of nozzles is significantly less than in the spray tunnel process.

KTL lines can be continuous or intermittent.

Continuous operation is when the movement of the workpieces is provided by a conveyor, while in the case of intermittent operation the workpieces are provided by a device for lifting between the tubs.

In addition to nozzles, many other accessories are used in surface treatment processes, which are also part of our nozzle product range.

Plugs, end caps, pipe holders and pipe couplings are also available.

As well as spoon nozzles (even in memory design).

Spoon nozzles are usually used as closures at the ends of zones or where higher surface impact are required.